EcoStapler - Staples EcoEasy Challenge

In Fall of 2009, Staples, Inc., the world’s largest office supply company, in a partnership with the Rochester Institute of Technology’s Golisano Institute for Sustainability launched the inaugural Staples Global EcoEasy Challenge. Three other female Mechanical Engineering students at UC Berkeley and myself (Cynthia Bayley, Griselda Cardona, and Sarah Thornton) entered the competition under the team name the Explosi-Divas.

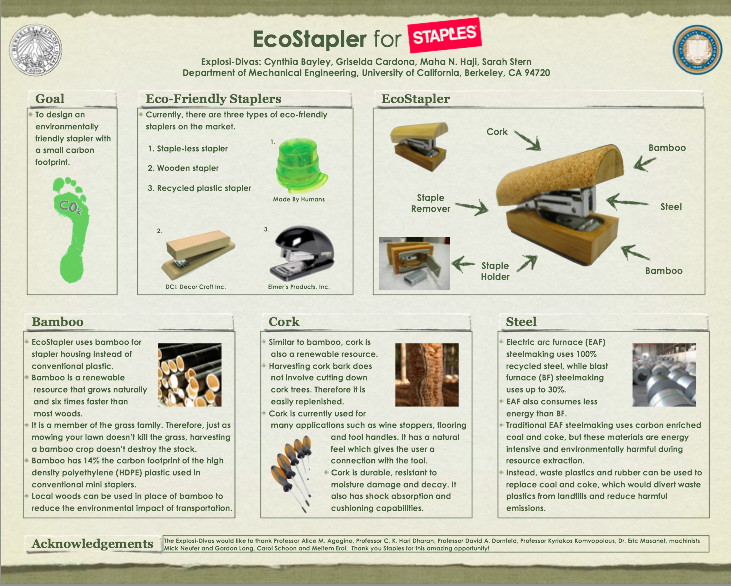

The goal of the competition was to develop an office product that represents greater environmental responsibility or sustainability. After submitting many preliminary concepts at the end of Fall 2009, the EcoStapler idea submitted by our team was one of the seven finalists to compete in the next round. Our product, the EcoStapler, is a mini-stapler whose housing is made from bamboo instead of conventional plastics. Additionally, the steel used from the stapler is made using an Electric Arc Furnace process that not only utilizes 100% recycled steel, but also incorporates waste plastics and rubber from car tires as reacting agents instead of additional iron ore or coke, both of which are highly energy intensive to extract.

During the competition, our team utilized a great deal of product design skills. We conducted market and user needs research as well as material research to examine the feasibility of replacing the plastic housing of a stapler with bamboo. Additionally, we did an entire Life Cycle Assessment on our modified bamboo stapler comparing it to that of a conventional plastic stapler to see that it truly was a more sustainable alternative.

After presenting our concept to the judges on April 20th, 2010 in New York City, the Explosi-Divas won first-runner up for our product. In addition to $5,000, our team won the chance to have our product sold on the market.